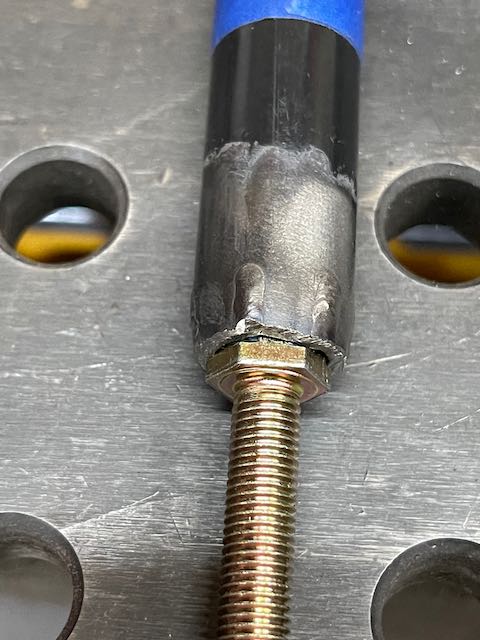

June 26th – I visited John, my welding guru, and he sorted out my problems. He cut the too short bolt off, drilled a hole in the remaining material, then turned down the head of a longer bolt to fit in the hole, and welded it all in place.

- Hole and turned bolt…

- …in place…

- …welded up. Result.

With the revised pushrod in hand, I hot footed it to the hangar, and what do you know, it worked a treat! The flaps and ailerons are now rigged per the plans, and all tie rods are fully engaged.

- Adjusted…

- …and secured.

Coincidentally, when I got back from the hangar, there was a surprise package waiting for me from the Sonex factory. Inside was another pushrod which complies with the drawing precisely. I suspect that this part would work, but as I have a successful installation, I don’t feel like taking it all apart to find out; I will closely monitor the weld on the installed pushrod, and keep this replacement to use if I see excessive wear occuring.

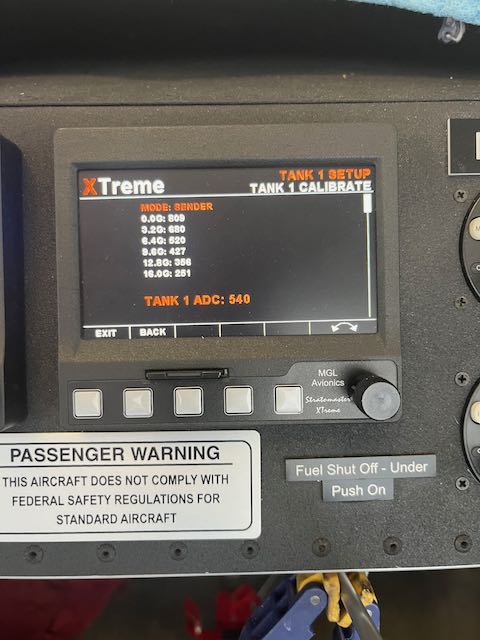

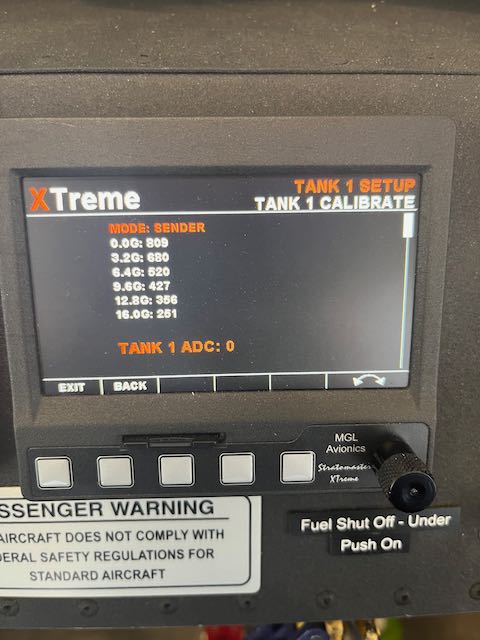

The next item on the punch list was to calibrate the Fuel Level indication.

I decided to fill up a bunch of gas cans with auto fuel and start following the calibration procedure in the MGL manual, but it became apparent that something was amiss. As fuel is added to the tank, data points are captured at various levels and programmed into the EMS, resulting in an accurate fuel indication. The initial indication seemed reasonable, but as soon as I added any fuel, the value dropped to zero and stayed there no matter how much fuel was added.

- Empty tank…

- …with fuel.

I did, at least, manage to calibrate a dipstick, but something was obviously amiss; time to reach out to Tech Support.

As the system includes components from different manufacturers, I contacted all of them, and discovered that there’s a good chance that I might have lead myself astray by using auto fuel. The majority of auto fuel has ethanol mixed with it to a certain degree, and the fuel probe is not calibrated for fuel with any ethanol. The tank is already drained, but the recommendation is to remove the probe, rinse away any remnants of ethanol, then try again with 100LL AvGas. That will be my first approach, with fingers crossed for an easy fix.

While I was waiting for a response from Tech Support, I dug out the final panel for the aircraft. This is the belly panel, which is recognized as the last thing to be attached, as once it’s in place, access to anything behind the seats, is awkward, to say the least.

I’m not going to polish it to a ridiculous level as it will be out of sight, and will probably get pretty grimy, but it was a good way to spend a few hours at the hangar until the temperature got in to triple digits and I called it a day.

I then took a little break from working on the plane, and headed off to Kansas City, MO.

Why, you might ask? Because this is where Jeff Schulz is based, and I think he may be the only person in the country who has a Letter of Authorization from the FAA to carry out training on the Sonex aircraft. He is also a guru on the type, having built three of them.

I had a most enjoyable weekend learning the ins and outs of the machine, I got a little under six hours of flight time and over twenty landings, which will stand me in good stead when the time comes to take to the air in my own aircraft.

- Jeff and his Sonex…

- …my turn.

With the flight training completed, another step towards certification and first flight has been checked off, and the punch list is getting shorter.

Stay tuned…