May 13th – The first thing I needed to do after the excitement of the first engine start was to get organized in my new space. I ordered a few things and moved most of the tools from the workshop at the house, out to the hangar.

- Tool Trolley…

- …re-purposed wing stands…

- …and a dog space.

Then it was on to rigging the controls; I started with the ailerons. I confirmed the aircraft was level, then fastened the control stick exactly vertical with some large zip ties.

- Stick vertical…

- …and secured.

A straight edge is used to project a line from the control surface to where the front wing skin overlaps the rear skin. A vertical measurement here sets the neutral position, with any adjustment necessary being made by moving the tie end rods in or out.

- Straight edge clamped…

- …that’ll do.

When the adjustments are made, it is important to ensure that the tie rod ends are sufficiently engaged on the threaded portion of the pushrods. There is a hole drilled in one side of the tie rod, if installation is correct, it is not possible to insert a piece of wire into the hole.

The ailerons went fine, and then I moved on to the flaps.

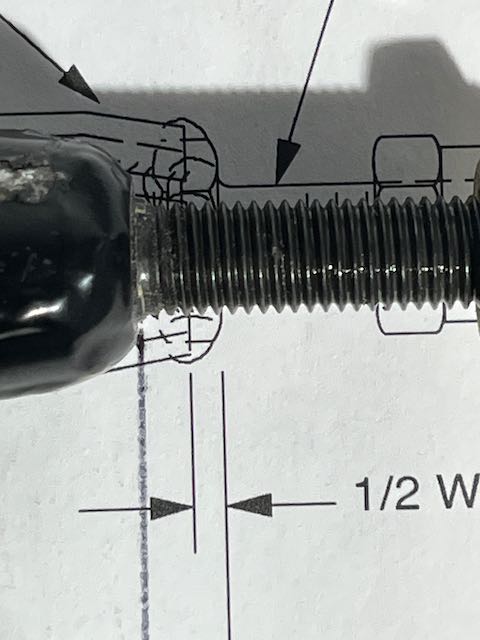

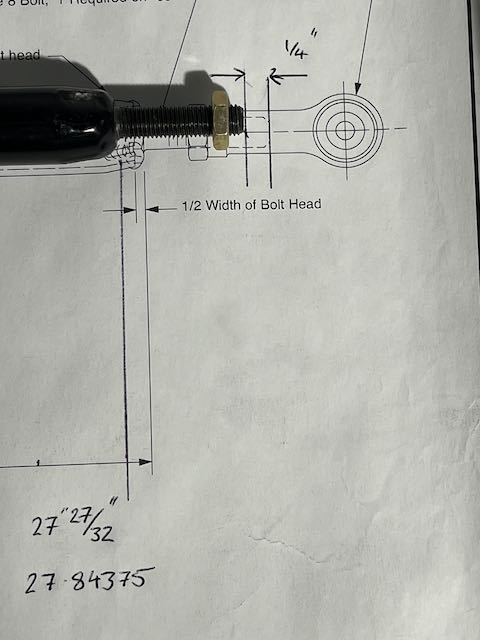

Here I ran in to a problem. The left side rigged out fine, but with the right side adjusted to the correct location, there was not enough of the threaded rod engaged into the tie rod end. After much head scratching, I could not figure out for the life of me what the problem was, so I started taking things apart again. When I pulled the pushrod and compared it to the drawing, it appeared to be about 1/4″ short, which would explain the issue. It also appeared that the dimensions of the drawing, which is drawn at 1:1 scale, were incorrect.

- Shorter than advertized…

- …should be 27 63/64″

We had had a spell of wet weather and the plans had been kept at the hangar which was very humid, but after taking them inside at home and remeasuring a couple of days later, the discrepancy was not as large, and the drawing dimensions were spot on. I can only assume that there was some expansion of the paper due to the humid nature of the environment they were kept in for a while.

Regardless of this issue, my pushrod was shorter than the drawing called for, so I contacted Sonex and requested a replacement part. In talking with them, there was some surprise at the issue and a few questions were asked about other parts of the build that might affect the position of various parts of the flap control run. I completed those parts of the build years ago, and everything seemed good at that time; several of the components were made by Sonex and the rest were ‘match hole drilled’ by the factory.

They did indeed send me another pushrod and it was about 1/16″ longer than my original part. Unfortunately, it did not solve the problem; it was closer, but there is still not enough of the rod engaged into the fitting. As this linkage will be subjected to a fair amount of load, this is not acceptable and I am going to have to come up with another fix. I have asked Sonex if they can make me a custom part with a slightly longer threaded insert and I am waiting to hear back from them. If they can’t help me, I will visit my local welding guru who helped out with the tailwheel control rod, to see if he can fabricate a part, or modify one of the pushrods that I already have.

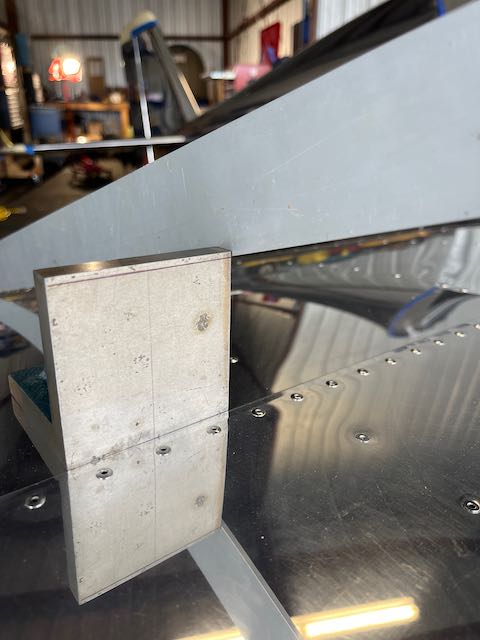

While I await resolution on that issue, I moved on to something that was bugging me, the gap at the wing root to fuselage surface. I ordered a different seal strip with the hope that I could squeeze it in to the gap, but when that proved impossible, I decided to bite the bullet and take the wings off again. It was a drier day than when we put them on last time and I found that with a relatively small amount of swearing and with a vast amount of green masking tape, it actually wasn’t too bad of a job.

- Lots of tape…

- …that’s…

- …better.

My hangar pal got a new bed.

I was looking for something else to do so I installed the covers for the landing and taxi lights.

- Cover on…

- …and protected.

It wasn’t until after I had finished the second one, that I realized that I hadn’t aligned the lights. Ah well, I’m not planning on doing any night flying just yet, so that’s a job for another day.

Still a few things on the punch list, but it’s getting shorter. Stay tuned…